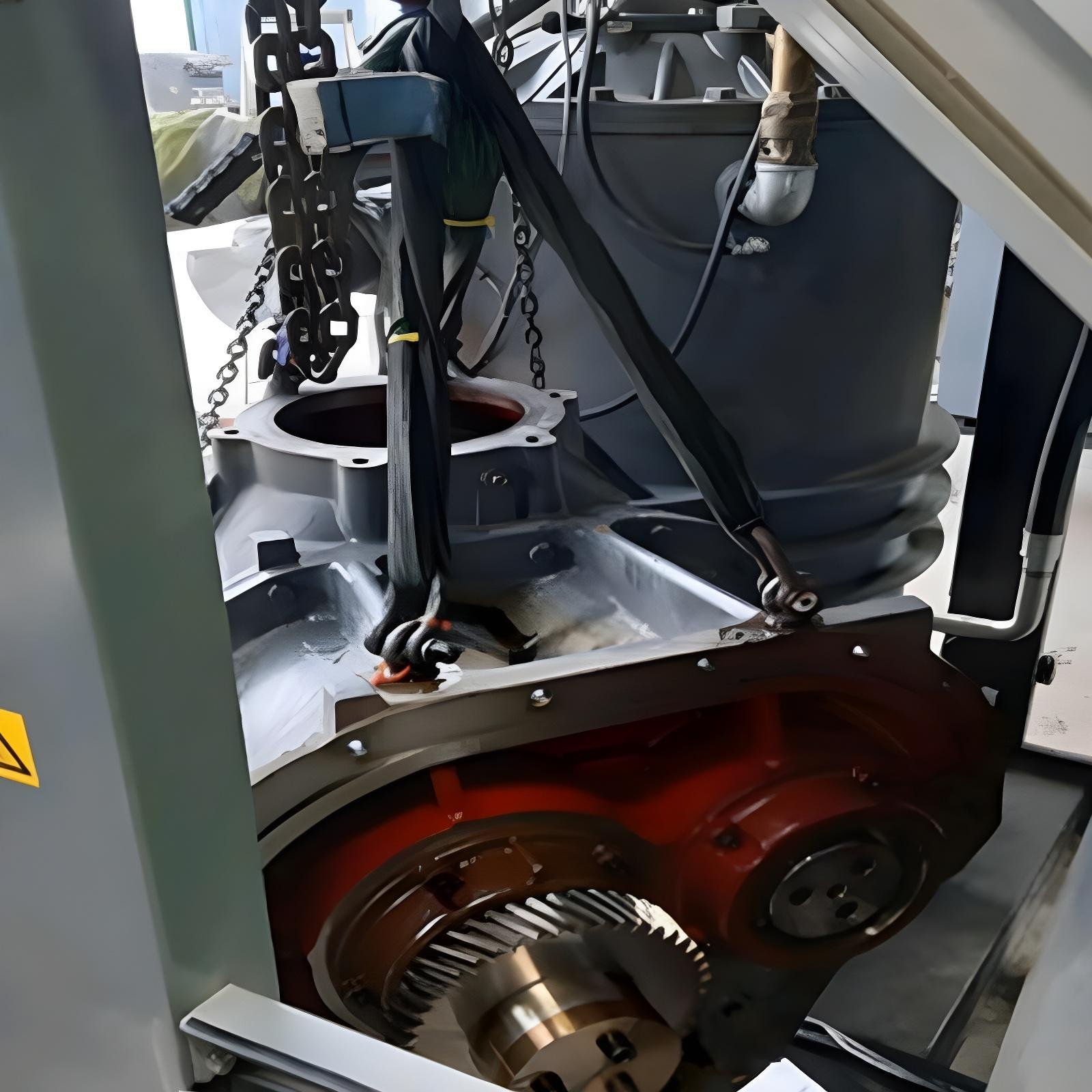

Screw Compressor Airend Reconditioning

We provide reconditioning services for both oil-free and lubricated screw airends.

Overview

Comprehensive Airend Reconditioning Solutions

We support both:

• Oil-Free Screw Compressor Airends

• Lube (Oil-Injected) Screw Compressor Airends

All work is carried out with strict quality control, inspection, and testing procedures to ensure long service life and dependable operation.

Oil-Free Screw Compressor Airend Reconditioning

Scope of service includes:

• Complete dismantling and inspection

• Rotor condition evaluation

• Bearing and seal replacement

• Housing inspection and surface correction

• Precision reassembly

• Performance and leak testing

• Rotor & Housing inspection and surface correction

• Rotor & Housing Teflon coating

• Internal clearance correction

Suitable for industries where air purity is critical.

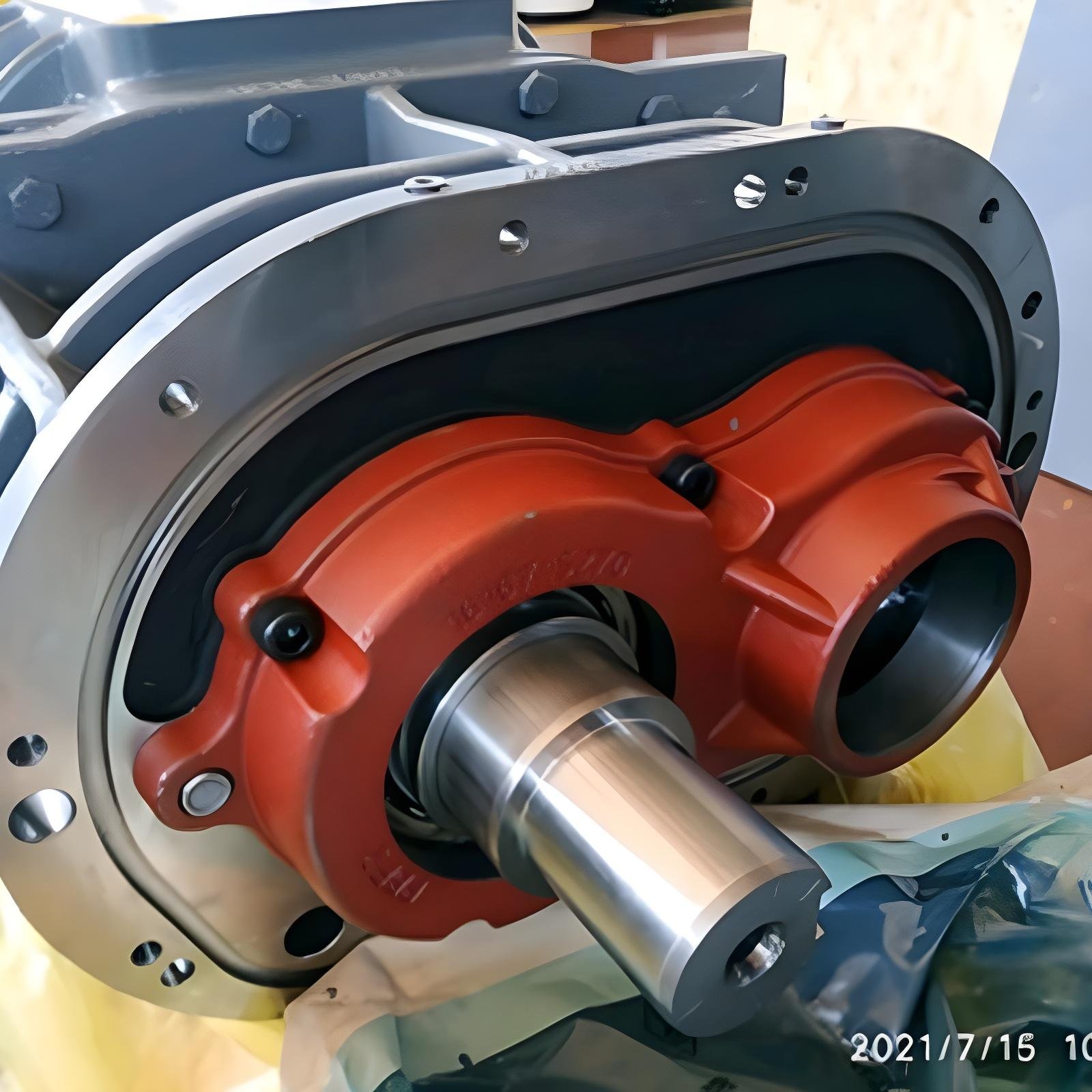

Lube Screw Compressor Airend Reconditioning

Scope of service includes:

• Replacement of bearings, seals, and wear parts

• Rotor inspection and alignment

• Internal clearance correction

• Cleaning and reassembly

• Functional testing under controlled conditions

Atlas Copco Z element Overhaul

- Sending your old air end (element) to us for refurbishment couldn’t be simpler…

- We stock refurbished elements from stage 1 to 6 and as well as competitive priced refurbished air ends for oil free compressors we stock stages 1 to 6 NON OEM NEW elements..

- Providing your air end turns we can normally fully restore the air end to full working condition like new with a TEST certificate to prove its condition..

Why Reconditioning Instead of Replacement?

• Significantly lower cost compared to new airends

• Restores original performance levels

• Extends service life by thousands of operating hours

• Reduced downtime

• Environment-friendly solution

• Suitable for multiple compressor models

Seals and Bearing Quality Assurance

We use high-quality seals and bearings designed to withstand demanding operating conditions. Each refurbished airend undergoes strict inspection to ensure reliability and durability.

• High wear resistance

• Long operational life

• Precision fitment

• Tested for endurance and performance

Highly Trained Technicians

Our service engineers are experienced in handling both oil-free and lubricated screw compressor airends. The team follows structured procedures and quality standards to ensure reliable refurbishment and consistent results across all service stages.

Testing & Installation Service

All refurbished airends are tested at site or under controlled conditions to verify performance and efficiency. A test certificate is provided after successful testing.

Our service team also offers professional installation support to ensure correct alignment, smooth commissioning, and long-term reliability.

‘ Don’t just replace, refurbish’

Atlas Copco Z element Overhaul

The screw element is the most important part of any screw-type compressor. It’s that part of the machine, where the actual compression takes place. It is the heart of the rotary screw air compressor. Often, the compressor screw element is also called air-end. They are constant flow (volume) with variable pressure compressors. Which mean that at a given speed (rpm), they always supply the same amount of air (in liters per second for example), but can do so at different pressures.

We deal all makes and models of screw element (airend) reconditioning / rebearing services in chennai, like Atlas copco, Elgi, Kaeser, Ingersollrand, etc,.

Why are they so popular

Since it’s a continuous process (as opposed to reciprocating piston compressors) they supply a steady, non-pulsating air flow, with minimum vibrations and maintenance. It will give maximum life time. They can operate 24/7, 365 days a year. The normal lifespan of a screw element is about 40.000 running hours, before a complete overhaul is necessary. (Subject to Proper maintenance of oil level. wear & tear of Bearings, Gear teeth, Shaft and Sleeve)

The Rotary Screw Element

Screw ELement containing two rotors (male rotor on the bottom, female rotor on the top) and the housing. The rotors have different kinds of bearings on both sides so they run smoothly for years without any maintenance. There are usually two pairs of bearings on both sides; bearings for radial loads (loads because of the turning of the rotors) and axial bearings.

The screw pushes to one side (the high pressure side) the rotors want to move to the opposite direction. The axial bearings take on this load and that the male rotor has an axle that sticks out with a gear on it. This is the driving gear. Sometimes it’s a pulley. The two rotors are also connected to each other by gears, these are the synchronization gears.

There is a sealing between the oil and the compressed air compartments, to prevent any oil from contaminating the compressed air.

How It Works?

Inside the compressor elements are two screws (called ‘rotors’) that turn in opposite direction. The rotary screw compressor is a ‘positive displacement’ compressor. The simply means, that the air is physically squeezed to gathers by an external force (like piston and scroll-compressors, which are also positive displacement compressors).

In the case of the rotary screw, the air gets trapped between the two rotors. The rotors have a special design for optimal efficiency and performance.

One rotor is called the ‘male’ rotor; the other one is called the ‘female’ rotor. Air gets sucked in on one side (cold-low pressure), gets trapped between the rotors, and discharged on the other side (hot-high pressure). This compression requires power, which is usually supplied by a big electro motor.